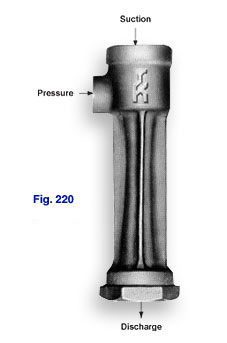

The Fig. 220 Jet Syphon is designed for use where solids or semi-solids must be passed through the pump.Typical uses include handling sewage and muddy water, cleaning cesspools and cleaning sludge out of tanks. Ejectors of this type can be used as pipeline slurry heaters for continuous processing. A high-pressure gas enters the syphon at the side, passes through an annular orifice, and discharges at high velocity into the throat. The suction material is drawn in through the open suction nozzle, is entrained by the gas and is discharged through the discharge connection at some pressure intermediate to suction and motive pressures.

The Fig. 220 Jet Syphon provides a straight, unobstructed passage for material handling, has no moving parts, good for pumping and mixing, and requires little maintenance.