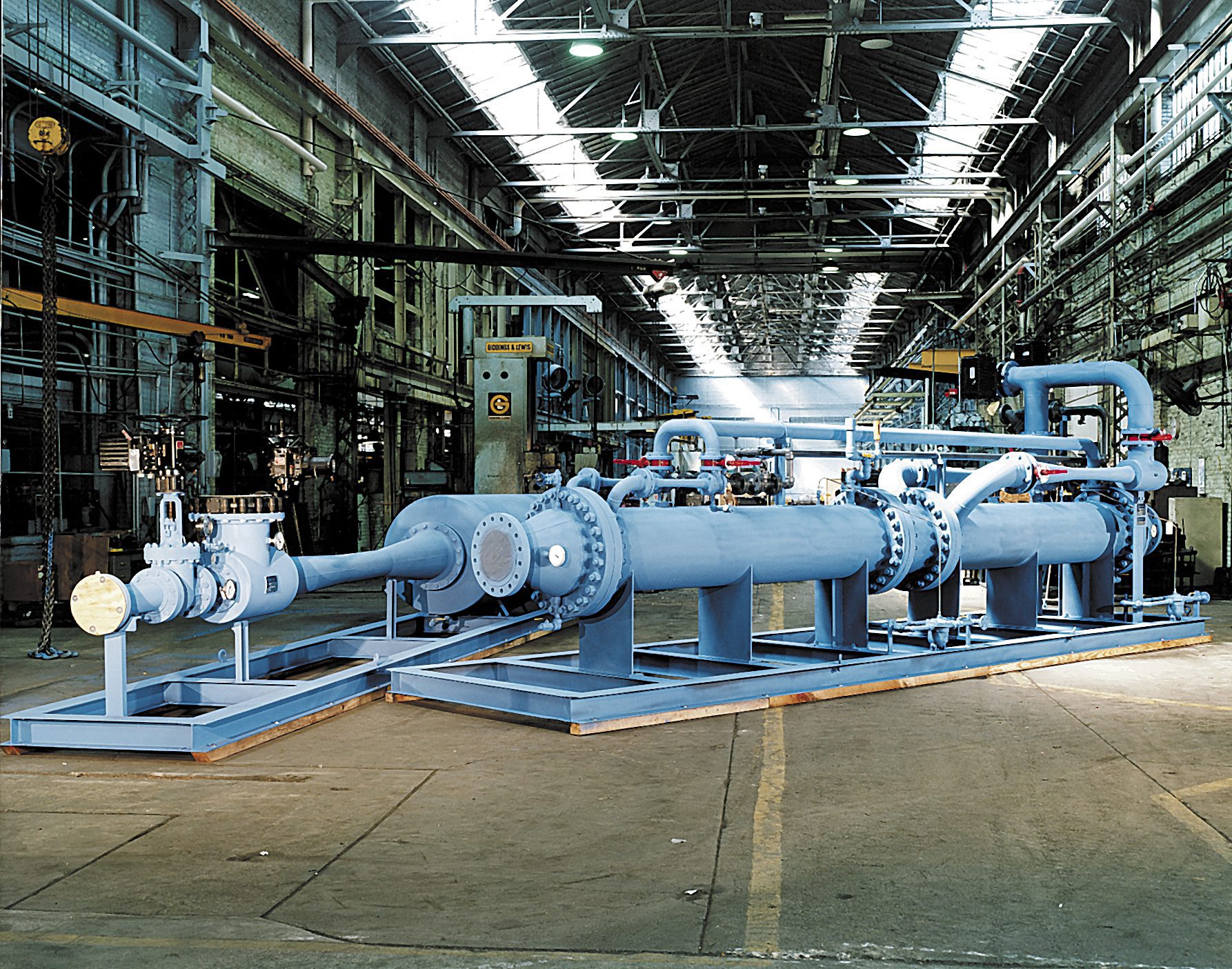

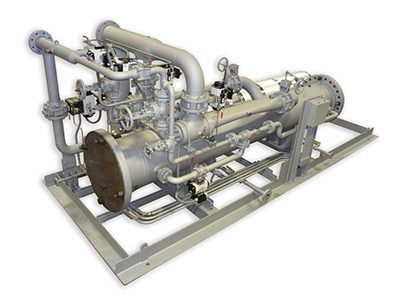

Schutte & Koerting has more than a century of experience in the design and manufacture of steam jet vacuum systems, steam jet heaters, exhausters and compressors, thermocompressors, scrubber systems, desuperheaters, valves, eductors, syphons, pneumatic conveying eductors, and ejectors.

S&K products are used in a multitude of industries including the Power generation, Steel and metal refining, Food and beverage, Fibers and textiles, Pharmaceuticals, Edible oil processing, Flavors and fragrances, Fertilizer production, Pulp and paper, Water treatment and desalination, Petroleum refinery, Petrochemical processing, Chemical manufacturing, Air pollution control, Shipbuilding, among others.

Our specialists are available to work with you to discuss your unique process requirements.

Single- and Multi-Stage Steam Jet Ejectors & Barometric Condensers.

Multi-Jet, Multi-Spray, Multi-Jet Spray

Venturi, Attemperator, Steam Ejector Atomizing, and other Desuperheaters.

Check and Pressure-Relief Valves, Throttle Trip and Three-Way Valves.

Steam Jet Pumps, Thermocompressors, Jet Blowers plus.

Continuous, Simplex, Slurry, Quiet, Circulating Heaters, plus others.

Pneumatic Conveying Eductors for Dry Solids and Eductors Using Liquid.

Water Jet Eductors, Tank Mixing Eductors, Steam Jet Syphons, and more

Ejector Venturi Gas Scrubbers, Vent Gas Scrubber Systems, and more.

Valve and Thermocompressor Refurbishments and Repairs by S&K.

Put an experienced staff of design and test engineers on your side. We’ll help to solve the most challenging vacuum process requirements. Our ability to design both standard products and custom equipment has been the basis for our longevity and success.

S&K offers a large inventory of standard and customizable products for quick delivery. Our in-house manufacturing and testing facility enables us to meet stringent deadlines and quality objectives. Competent application engineers, designers and technicians work toward optimizing existing products and developing new solutions. The company has a worldwide presence with knowledgeable sales and support representatives.

Submit a Quote Request Form for your specific product, application, spare parts, or service. If unsure of what product is needed, complete a General RFQ Form. Responses are typically acknowledged within one day.

Request for Proposals should include specifics as outlined on the Quote Request Forms. Provide process conditions, application details, suction conditions, motive conditions, discharge conditions, system requirements, utility conditions, construction, and other specifications or requirements, as outlined in the Quote Request Forms.

As an international industrial power and process equipment manufacturer, our products are installed in a wide range of projects. Take a look at a sample of our products and capabilities – we are constantly adding new images.

We invite you to use our online library for blog articles about industry developments and the latest news, product brochures, technical references, and product applications. And if you have questions, get in touch with us.