By Howard S. Agnew, Application Engineer

Schutte & Koerting

Cutting plant maintenance and operation costs, including labor, replacement equipment and production lost in down-time, is everybody’s objective. Sometimes, however, opportunities are missed because of a tendency to meet such problems with a conventional solution. Reappraisal of every plant function, even the most simple, for alternative methods can lead to cost savings well worth the effort involved.

One group of alternative equipment, which should be considered, is jet ejectors. Ejectors offer unique, multi-function capabilities in a single, compact unit. Useful in many applications to pump, mix, heat, cool or produce vacuum, they are among the most versatile of all industrial equipment.

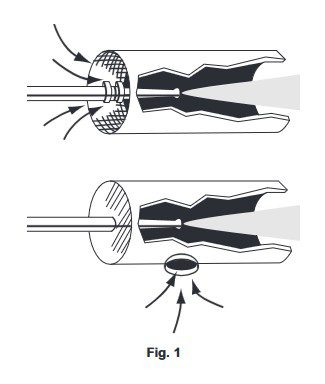

In brief, all jet ejectors operate on the Bernoulli Theorem. A stream of fluid under pressure (liquid or gas) is passed through a nozzle. As it discharges from the nozzle the fluid’s pressure is decreased, its velocity increased. This jet, then, has the ability to move some other substance through the principle of entrainment: the production of a strong suction through a small inlet which will draw in, entrain, a variety of gases, liquids, or even powdered or granulated solids, as in Figure 1.

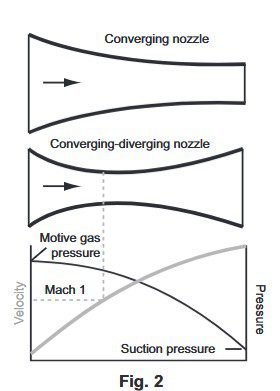

Though the principle and the equipment which apply it are simple, the designs of the nozzle and the discharge pipe (commonly called the diffuser or venturi) specific to the demands of the application are quite sophisticated. Figure 2 illustrates two generalized nozzle constructions and plots the relationship between pressure and velocity.

Diffuser construction can be similarly generalized as in Figure 3. At the entrance to the diffuser, the high velocity stream from the nozzle is surrounded by the entrained suction fluid, the two are intimately mixed in the converging section, then released in a uniform mixture through the diverging section.

Because of their extremely simple construction, ejectors have a number of inherent advantages over other types of equipment. There are no rotating parts of bearing to wear out or require lubrication, installation and maintenance are simple, and the only adjustment normally needed is some type of flow control.

Because they are self-priming, ejectors are particularly suited for intermittent, unattended or remote operation. And since ejectors can be manufactured from practically any machinable material or lined with a variety of materials, they can be made to resist corrosion/abrasion.

The adaptability of jet equipment to diverse applications makes a brief summary of its utility impossible. As a general rule, the jet equipment deserves special attention whenever several operations—mixing, pumping, heating, proportioning, transfer—must be performed. A comparatively simple ejector arrangement often can combine these operations and, thereby, replace several pieces of conventional equipment.

Ejector nozzles are either converging or converging-diverging, with the correct choice depending on the motive fluid and the operating conditions. In both cases the nozzle is carefully designed to achieve maximum conversion of pressure energy into velocity energy.

The diffuser provides thorough mixing of motive and suction fluids and converts velocity energy back into pressure energy.

Plant ventilation, and the related area of pollution control of plant exhaust, is another area where jet equipment can contribute efficiency and lower costs. Ejector-venturi fume scrubbers will simultaneously exhaust and scrub fumes with the water of solution stream, which serves as the motive fluid. In-plant ventilation can also be effected with jet equipment, and especially useful approach in areas where corrosive fumes are present.

In the production of propane waxed, formed cups, for example, fumes will corrode or block electric fans. A single motive source for pressurized air or water will operate a system of ventilation ports to move large volumes of air for draft production in many separate plant areas.

Related ejector equipment, blowers and blast nozzles, are used to increase draft in stacks and chimneys as well as exhaust gases in shipboard applications. The compact size and reliability of these blowers, like that of all ejector equipment, provides the capability for installation in minimal or remote spaces with no need for complete accessibility.

Though water is a necessary component of many process streams, it can also present problems in plant drainage. Draining ground water from any remote plant area, subterranean or surface, reveals another ejector advantage: portability. By locating the motive pump in a permanent installation the eductor can be moved to problem areas or since intermittent operation and self-priming are additional jet capabilities established permanently wherever the problem recurs.

Ejector portability can be equally important in those often difficult, but necessary, house-keeping operations. Drainage of sumps, sludge removal from tanks or tank cars, and cleaning with high velocity streams, are common uses.

The ability to perform pumping suction, or fume evacuation without electricity can make jets the equipment choice for hazardous or inflammable conditions. The alternative, a motor in an explosion-proof housing to run a pump, can be an expensive proposition with some remaining risk as well as periodic down-time for inspection and maintenance because of the pump’s high operating speed.

Examples of this application include the use of ejector to eliminate gas pockets in grain elevators, ship’s holds, or any space where inflammable gases may collect by applying a slight draft or vacuum. Water or steam jets, operating without electricity, are also in use in the pickling line towers of sheet metal rolling mills to eliminate pocketing of H2.

The expanding number of nuclear power plants has added a new category to the “hazardous conditions” heading, but jet equipment is up to the task. Two examples are the use of twin element steam jet vacuum systems to pull vacuum on the main condensors, and stream jet syphons (high lift suction of 22 ft) enclosed in in-line units to handle radioactive wastes. Handling less exotic, yet still “difficult” materials, such as acids or other corrosives, or exhausting their vapors can damage pump components, especially the seals which are an inherent weak point; pump adaptations specific to these problems are often difficult and expensive and involve costly maintenance. Ejectors constructed of appropriate materials can avoid all these problems.

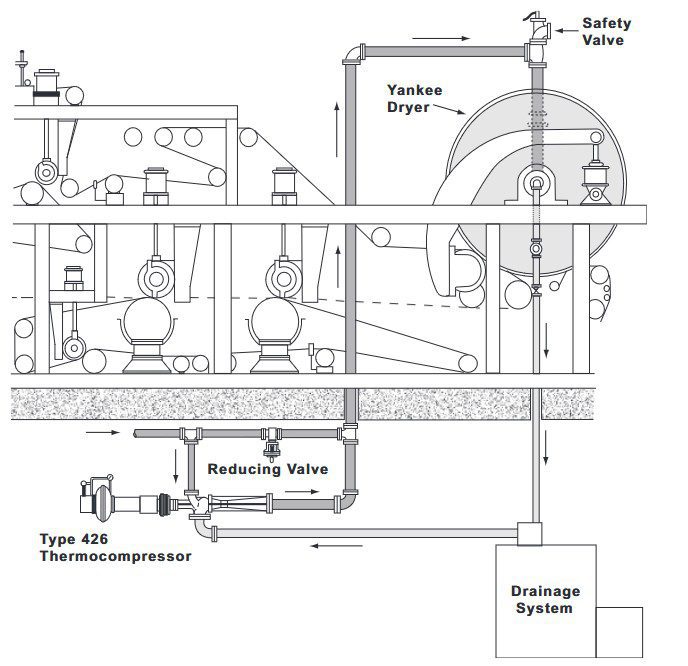

One of the most contemporarily advantageous members of the ejector equipment group is the gas compressor which uses a high pressure gas to entrain and mix lower pressure gas for discharge at an intermediate pressure. When both gases are steam the unit is often called a thermocompressor. Thermocompressors have obvious advantages in an age of rising energy costs because they recirculate low pressure steam, “waste steam” in happier times, to extract more work.

One typical use of thermocompressor is with a Yankee dryer, though a similar arrangement may be adapted for any plant seeking to economize on its steam costs. Here, high pressure steam entrains low pressure steam for discharge into the dryer. Automatic regulation is accomplished by means of an air-operated pressure controller and either a diaphragm or piston operator on the spindle. Because the spindle can reduce flow without reducing the energy available per pound of gas, the compressor utilizes the maximum energy available at all flow ranges.

Applications related to these examples in function or object are numerous. Eductors mounted permanently in tanks will fill and continuously agitate tank contents. Pipeline heaters are related to the sparger nozzles and circulating heaters necessary for many process vessels. There are still other classes of ejector equipment designed for functions not already mentioned. Eductors equipped with hoppers will efficiently handle dry materials by entraining and mixing solid with fluid either in a continuous process or for discharge into batch tanks. Others serve to produce vacuum or in combination with mechanical pumping to achieve a broad range of process purposes.

Pipeline heaters are related to the sparger nozzles and circulating heaters necessary for many process vessels. There are still other classes of ejector equipment designed for functions not already mentioned. Eductors equipped with hoppers will efficiently handle dry materials by entraining and mixing solid with fluid either in a continuous process or for discharge into batch tanks. Others serve to produce vacuum or in combination with mechanical pumping to achieve a broad range of process purposes.

As a brief summary, an ejector should be considered for any job which involves one or more of the following functions:

In any one of these broad categories an ejector may prove to be the most economical solution. The best choice, of course, depends upon a careful analysis of alternative, including the energy requirements of each. Since an ejector operates on energy contained in a pressurized fluid, the cost to supply this fluid added to the cost of the ejector must be the basis of evaluating the economics of a particular application.

Maintenance cost, on the other hand, is a very minor item with ejector equipment but can make a centrifugal pump one of the most costly items in a plant. Steam is often used as the motive fluid for jets, and the cost of steam is not what it was, but it remains the largest single source of heat energy in many process plants. Using ejector equipment to exploit this existing energy source more efficiently may well pay economic dividends.

In some cases, a particular capability of an ejector will, in itself, make it the clear choice for an application, e.g., the self-cleaning of flow-through continuous slurry heaters, the wide-range of available materials which simplify handling of corrosives, or the low maintenance and self-priming features appropriate for remote locations or intermittent operation.

In other cases, the somewhat higher pumping efficiency of a mechanical system or either the cost or lack of pressurized plant steam, pressurized water, or shop air may dictate that conventional pumping be used. And, in other situations, combination systems using mechanical pumping to supply motive force in isolation while ejector equipment performs the actual function may prove best.

Whatever the job to be done the choice of the most efficient and economical method should include a thorough investigation of equipment capabilities and a comparison of the total costs of operation—acquisition, installation, energy supply, maintenance—of both conventional and alternative equipment like jet ejectors.

One example of a comparatively simple ejector combination is used for the continuous cleaning and softening of the felts in papermaking machines. With a steam syphon and water eductor, the detergent solution is prepared from concentrate and water in correct proportion, the solution thoroughly mixed, then heated, and finally applied in a pressure spray to the, moving felts—all in a continuous and efficient process.

Maintenance is minimal because these are no moving parts in either ejector while the use of plant steam and water obviates the need for pumps, holding tanks, agitators, and heaters. Similar assemblies have applications in most plants: continuous heaters connected directly to steam, water, and discharge lines provide pressurized hot water for high velocity cleaning and wash down; instantaneous heaters with a lever and cock assembly to turn water on first, then steam, are widely used for warm water emergency washing in laboratories and plant areas where safety showers are required.

Transfer of slurries, whether process streams or unwelcome plant sanitation problems, can be troublesome. A jet syphon similar to the type used in the paper industry is easily adaptable to the transport of slurries and is often preferable in handling slurries with abrasive solids which can wreak havoc on pumps. Iron ore slurries, for example, are entrained, transported from the mine and discharged on the surface. The pump which supplies the motive to the eductor is isolated from the damaging solids while the eductor moves the slurry—a combination system which can be used with practically any heterogeneous stream.

Ejector—A general term converging all types of jet pumps, which discharge at a pressure intermediate to motive and suction pressures.

Injector—A particular type of jet pump (like a Boiler Injector) which uses a condensable gas to entrain a liquid and discharge against a pressure higher that either motive or suction pressures.

Syphon—A liquid jet pump using a condensable vapor, normally steam, as a motive fluid.

Jet blower—A gas jet pump which pumps gas against very low differential pressures.

Exhauster—A gas jet pump using a liquid or a gas as motive fluid.

Eductor—A jet pump using a liquid as motive fluid.

Jet compressor—A jet pump used to boost gas pressure.

Gas scrubber—A liquid jet pump which pumps gas against very low differential pressures. They are also called “fume scrubbers” and are used to scrub gases and obnoxious fumes.