By Harry Stratton, Schutte & Koerting

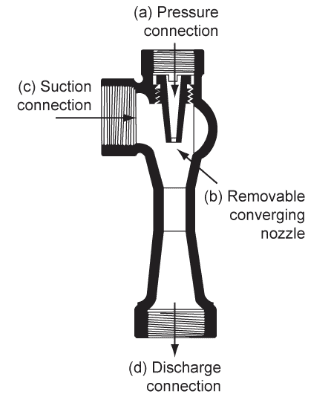

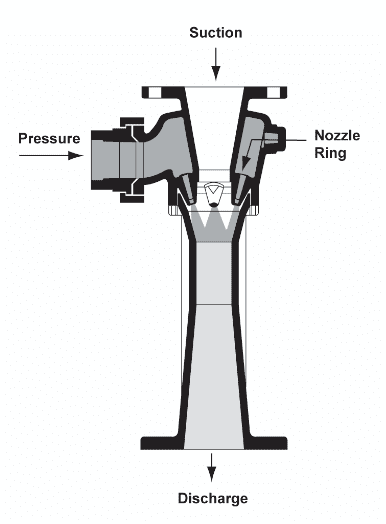

Liquid Jet Eductors are unconventional pumps and, therefore, are often overlooked when pumps are being evaluated for new applications. Eductors operate according to the Bernoulli theorem – kinetic energy of one liquid can be used to produce flow of another. Because moving fluid is essential to the operation of an eductor, the device may be defined as a jet pump that uses pressurized liquid, supplied by another pumping source, as motive fluid to modify and alter the pumping system’s fluid-handling characteristics, Fig. 1.

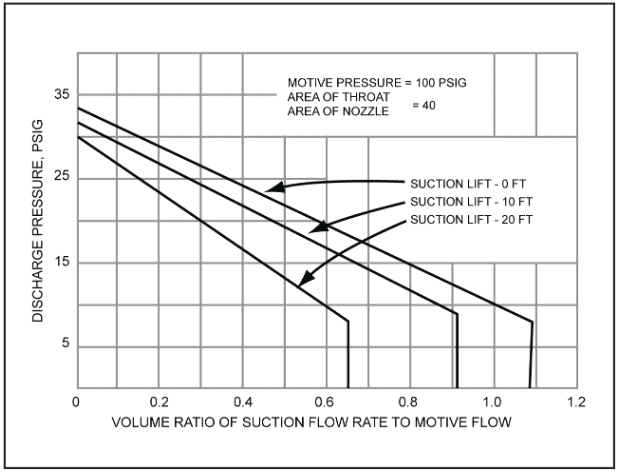

Theoretically, maximum performance of eductors can be precisely calculated. But in practice, performance is affected by energy losses associated with mixing two fluids and by frictional losses in the diffuser. It is important therefore, to remember that actual performance will be lower than the theoretical maximum. As a result, eductors are designed according to both theoretical and empirical relationships. Shape, size, geometry of the mixing chamber, distance between the nozzle and diffuser, and the dimensions of the nozzle on the diffuser are developed from calculated designs and modified after prototype testing. Figure 2 shows performance characteristics of eductors.

In addition to their self-priming characteristic, eductors have no moving parts, require no electrical power, and may be installed in remote or inaccessible locations – any place a pipe run can be made. Moreover, they may be made from any machinable material, as well as from pastics such as

Teflon, Kynar, Haveg, polyester, fiberglass, and polyvinyl chloride (PVC). With such a wide range of material selection options, resistance to almost any chemical solution can be provided.

The range of applications for which eductors may be used is quite broad. Eductors may be classed into several groups, according to type of service they are intended to provide.

Fig. 1. General-purpose eductor can be used for both pumping and blending service. Static pressure at the entrance to the nozzle (a) is converted to kinetic energy as the motive fluid flows freely through the converging-type nozzle; (b). This action results in a turbulence, or high-velocity stream of liquid, that entrains the fluid from the suction connection; (c), causing a slow

mixing of fluids at an intermediate velocity. Diffuser section converts velocity to pressure at (d).

Fig. 2. An abrupt change in suction capacity occurs when discharge pressure exceeds the design point of approximately 8 psig. Because of this performance characteristic, not all eductors are designed for peak efficiency. It is usually more advantageous to design eductors for greater capacity or for excess discharge pressure, whichever is more likely to occur. This design gives the eductor a wider span of performance than the limited range when designed for peak efficiency.

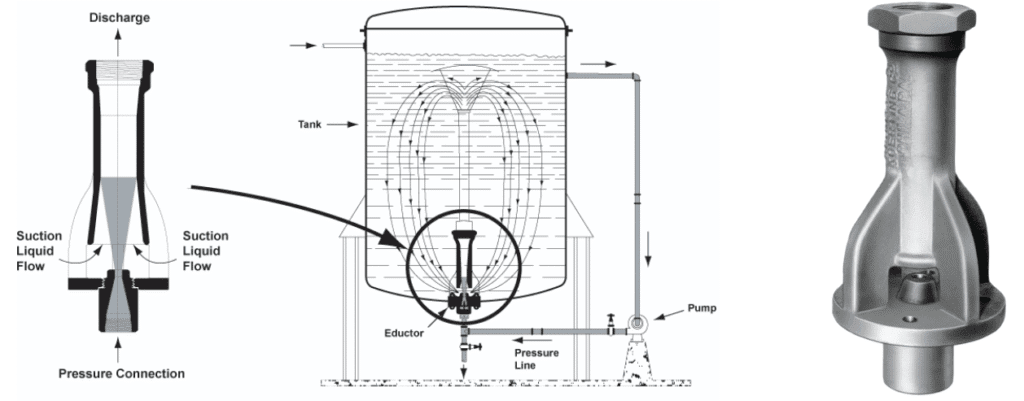

Fig. 3. Tank mixer located at base of tank has external pressure connections under the tank. These eductors are also used for fluid agitation or for increasing pumping capacity. Each unit is usually designed for a specific entrainment ratio. The design is determined by the quantity of tank fluid, the ratio of the mixture desired, and the depth of the tank.

General-purpose eductors, used in pumping and blending have a generally broad performance span, rather than a high peak-efficiency point. This type of eductor, Fig. 1, is usually constructed of iron, bronze, stainless steel, or PVC. Typical applications include cesspool pumping, bilge or sump pumping, and condensate removal.

Mixing eductors, designed for mixing and blending, usually have pressure connections outside the tank containing the fluid to be agitated. A very simple form of mixing eductor, Fig. 3, can entrain approximately 3 gallons of fluid for each gallon of motive fluid. Another general-purpose mixing type is the proportioning eductor. It may be equipped with regulating spindles to throttle flow of motive fluid. The use of a spindle increases agitation. Applications including mixing hydrocarbons with caustic or copper chloride slurries to produce emulsions, and proportioning liquids in chemical processing industries.

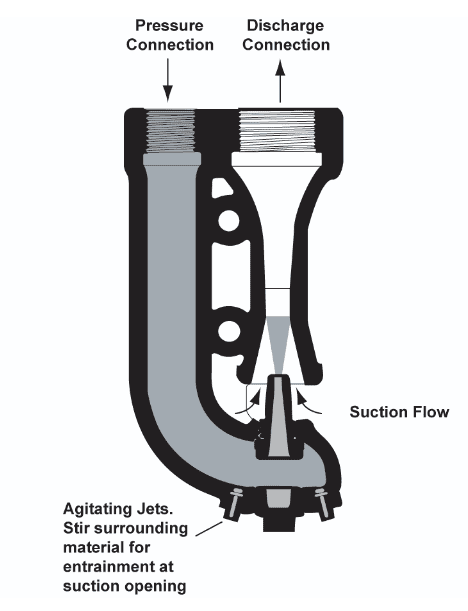

Sand and mud eductors are used for pumping out wells, pits, tanks, sumps, and similar reservoirs where sand, mud, slime, or other dense materials settle and accumulate. The lower pressure portion of the pressure chamber is fitted with a ring of agitating nozzles, Fig. 4, to stir sediment and, thus, cause maximum entrainment of solids. The submerged jet can thus pick up and move suspended materials.

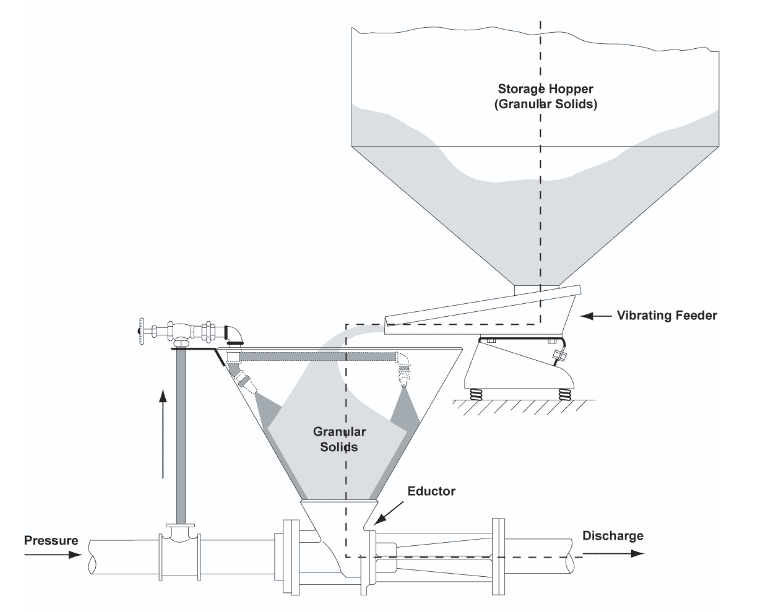

Solids-handling eductors are of two basic types: hopper and annular orifice. The hopper eductor, Fig. 5, is designed to handle slurries or dry solids in granular form, and may also be used for ejecting sludges from tank bottoms, pumping sand from filter beds, and washing or conveying granular materials. A typical construction uses cast iron with a hardened

steel nozzle and throat bushings. In operation, the washdown nozzles are adjusted to provide smooth flow down the hopper sides, thus preventing bridging of the material while the liquid collecting at the hopper bottom seals the eductor suction against excess air intake.

Designed primarily as a siphon, the annular orifice eductor is used when the material being handled tends to agglomerate and gum up when wet; intimate mixing occurs in the throat, preventing clogging. The unit is installed directly over the mixture discharge tank. Annular orifice eductors have also been used successfully for handling and mixing hard-to-wet solids.

Fig. 4. Agitating jets, mounted in a circle, discharge into accumulation of sand, mud, or sludge. Heavier materials become dislodged and are suspended for entrainment at suction opening.

Fig. 5. Slurries or dry solids (flowable) may be moved using an arrangement that prevents bridging of material and, at the same time, prevents excess air from being drawn into the pressure line.

Multinozzle eductors, Fig. 6, are designed for special applications in which the suction fluid contains solids or semisolids. They are used primarily for large flows at low discharge heads. Because these units have relatively large air-handling capacities, they also may be used for priming large pumps when air pockets cause loss of prime.

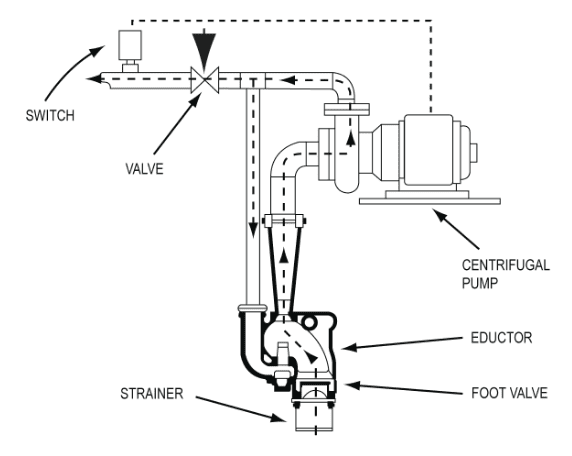

Deep-well eductors are recirculating-type systems used with mechanical pumps to draw commercial, industrial, and residual water from deep wells. These eductors are used to lift water and maintain net positive suction head (NPSH) at a conventional mechanical pump at the surface, Fig. 7. The deep-

well eductor, with hose connections attached to the suction and discharge inlets of the motive pump, is lowered into the well casing. Initial priming is

required and maintained by a foot valve at the suction inlet of the eductor. When the surface pump is operated, flow through the eductor entrains and lifts water from the well lifting it. A restricting valve at the surface diverts the eductor suction volume through the eductor pipe loop. Capacities of this type of system depend on depth of the well and capacity of the surface pump.

Fig. 6. Multinozzle eductors are designed for handling fluids that contain solids or semisolids. The arrangement shown uses six nozzles; the number increases for sizes larger than 6 inches. This type is used primarily for large flows at low discharge heads.

Recirculating eductor systems employ a piping and valve closed-loop recirculating system similar to the deep-well arrangement. This bypass return of a portion of the pump discharge through the eductor develops a vacuum to draw secondary fluid into the system, Fig. 8. Metered flow controls eductor volume introduced into the pump system. Generally, this volume is much lower than in most eductor systems.

Priming eductors are designed mainly as priming devices for mechanical pumps. These water jet exhausters are used to remove air rather than water. Liquid jets are not well suited for pumping noncondensables; therefore, capacities are low. However, the volume being primed is usually small, so low capacity is not a limit to operation. When larger volumes are encountered, such as in condenser water boxes, it is more feasible to use an exhauster. Eductors have approximately one-fifth the air-handling capacity of water-jet exhausters when supplied with similar motive quantities and pressures. The jet nozzle is replaced with a solid-cone spray nozzle to convert a water jet eductor to an exhauster. This nozzle contains helix-shaped blades arranged in a spiral, and imparts rotation to the stream and increases entrainment capability. Multinozzle exhausters are also available.

Fig. 7. Combination system, with a surface-mounted pump of a conventional design, may be used if an eductor will provide net positive suction head by recirculation of a portion of the pump output. In effect, this system is “trading” a portion of the pump capacity (volume) for increased lift (pressure at intake).

Fig. 8. When a blended, metered in-flow of liquid is desired, a portion of the pump output may be bypassed and recirculated through an eductor. The suction from the eductor will pick up added liquid for direct discharge into the pump suction line. This method is used when the ratio between motive fluid and added fluid is high.