When production reliability, product purity, and regulatory documentation matter, process plants need equipment that performs predictably, integrates cleanly, and supports long-term maintainability. Partner with a chemical process equipment manufacturer built for demanding chemical, petrochemical, pharmaceutical, and other process-industry environments.

At Schutte & Koerting, we design and manufacture industrial process equipment with an engineering-first approach, responsive quoting, and a quality system built on documented conformance.

Equipment selection impacts safety, throughput, emissions control, energy use, maintenance burden, and audit readiness. A reliable chemical process equipment manufacturer supports your operation with:

Strong industry compliance depends on risk control, documentation, and disciplined fabrication practices.

S&K equipment selection and project support can align with commonly referenced industrial standards and quality expectations, including ISO-based quality management and code-driven fabrication requirements such as ASME. If your project requires specific materials, inspection hold points, traceability, third-party verification, or export documentation (including PED or CE deliverables), include those requirements in the RFQ so the documentation package and manufacturing path align with your internal standards and destination requirements.

Process reliability depends on equipment that matches real operating conditions. The right configurations support stable temperatures, dependable vacuum performance, controlled flow behavior, and effective emissions handling, while reducing maintenance burden and supporting documentation requirements. As experienced chemical processing equipment manufacturers, S&K supports engineered selection, custom configurations, and sizing guidance for demanding process environments.

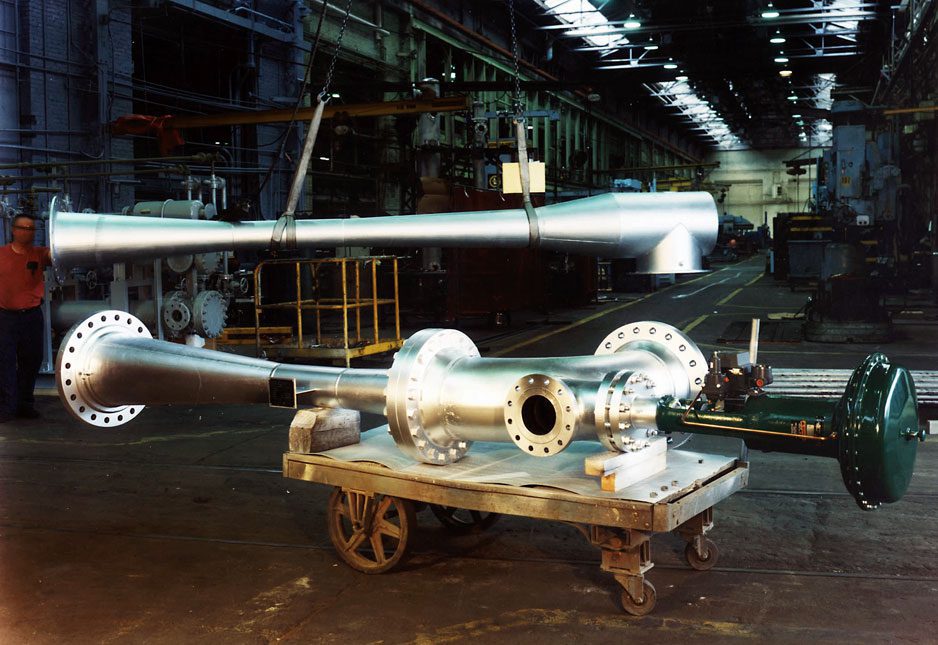

Desuperheaters and thermocompressors support utility control where steam quality directly impacts process stability. Desuperheaters reduce and control steam temperature to protect downstream equipment and maintain consistent operating conditions, while thermocompressors recover and recompress low-pressure vapor or steam to improve efficiency in suitable applications. For plants evaluating chemical processing equipment manufacturers, proper steam-side selection helps reduce variability, support repeatable outcomes, and improve overall uptime in demanding service.

Eductors and pneumatic conveying eductors provide dependable transfer and movement using the Venturi principle, helping reduce maintenance associated with rotating equipment. Eductors can pump, mix, or move process streams without moving parts, supporting chemical services where reliability and simplified upkeep matter. Pneumatic conveying eductors move dry solids using motive air, offering a practical option when layout constraints, wear concerns, or maintenance access drive equipment decisions for a chemical process equipment manufacturer partner.

Steam jet vacuum systems (ejectors) support vacuum generation and vapor handling across a wide range of process duties, where performance must be predictable under variable loads. Proper configuration depends on operating conditions, required vacuum level, and the nature of vapors and non-condensables. When comparing chemical processing equipment manufacturers, engineered selection support helps align ejector systems to the application, avoid undersizing or excess utility use, and maintain stable operation during production changes or startup conditions. Clear process data at the RFQ stage further improves sizing accuracy and long-term system performance.

Extraction check valves, throttle trip valves, and venturi scrubbers address core protection and environmental control needs in chemical processing environments. Extraction check valves help prevent reverse flow to protect equipment and improve line stability, while throttle trip valves support controlled operation and protective functions where dependable valve behavior is required. Venturi scrubbers provide gas-liquid contacting for particulate and absorbable gas removal (application-dependent), supporting emissions-handling goals when specified by the process and documentation requirements for chemical process equipment manufacturer selection.

A chemical process equipment manufacturer has to work within your layout, utilities, turnaround windows, maintenance access, and documentation requirements.

S&K supports custom and engineered solutions with:

Long-term value comes from equipment that stays serviceable and supported.

Support options include:

To speed selection and pricing from chemical processing equipment manufacturers, provide:

Selecting the right chemical processing equipment involves technical, regulatory, and operational considerations. These frequently asked questions address common concerns around customization, materials, documentation, quoting, and long-term support so you can move forward with confidence and clarity.

You should expect disciplined documentation, verified fabrication practices, and an engineering approach that accounts for process conditions, material compatibility, and code or customer requirements (such as ASME, where applicable).

Yes. S&K is an engineering-oriented manufacturer that offers engineered-to-application solutions and responsive quoting support across its process equipment product portfolio.

Material selection should be tied to your process stream, temperature and pressure, corrosion risk, and required documentation. Providing these conditions up front helps align the equipment configuration and quoting paths with your operating requirements.

Complete process conditions, performance targets, utility requirements, material expectations, and documentation requirements reduce back-and-forth and improve sizing and pricing accuracy. Targeted RFQ forms can also help standardize inputs.

S&K supports applicable products with repair, refurbishment, replacement, and inspection services, including valve-focused service and refurbishment programs.