1-Specify minimum turndown

2-Keep superheat high

3-Provide topnotch system engineering

By C. G BLATCHLEY, Chief Engineer, Schutte and Koerting

No desuperheater operates alone; it is always part of a system made up of many interacting components. To get satisfactory performance and satisfactory economy, you must specify only the capability you really need from your system and no more. Over specification involves unnecessarily high costs. Sometimes it even defeats its own purpose, leading to unsatisfactory operation. In a previous desuperheater article (POWER, Feb 1962, pp73-75) we covered equipment types available and characteristics that affect their application. Now let’s look at the basic three rules, guides to a satisfactory and economic desuperheater installation.

Turndown-more properly, maximum and minimum flows-affects first cost more than any other factor. It’s a common error to specify much more turndown than is really needed. The designer usually recognizes the increased cost; he decides to pay for a supposed performance margin. But in fact, higher-than-necessary turndown often hurts system performance.

In a recent case, maximum flow specified was ten times the immediate need-idea was to take care of anticipated 5-yr growth. So the desuperheater was asked to operate between 1% and 10% of its full flow rates instead of the 10% to 100% it was designed for. Here an attempt at foresight doomed the desuperheater system to poor performance right from the start.

Here again, designers tend to write more strict specifications than they need in the hope of getting better performance. But just as in the case of turndown, over-specification leads to higher first cost without necessarily enhancing performance.

Residual superheat is superheat remaining in the output steam. Amount you need generally fits into one of these groups:

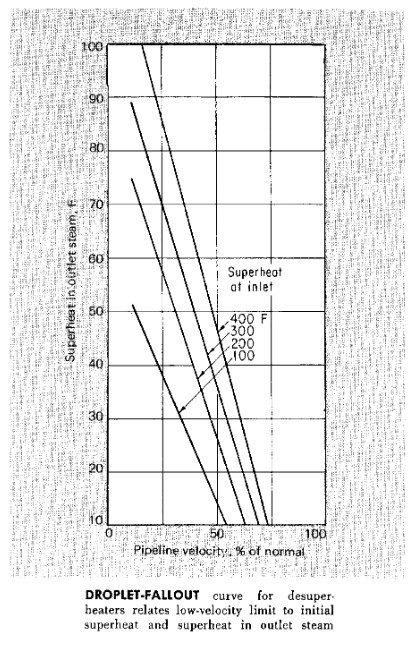

This fallout phenomenon was discovered empirically. Probably it happens because lower temperature differences reduce heat-transfer rates. Each droplet must stay in suspension longer before it can evaporate, and turbulence must be sufficient to sweep saturated steam from around water droplets. So when you’re operating close to saturation, steam velocity (and turbulence) have to increase to avoid fallout.

A desuperheater is not a single piece of equipment that succeeds or fails on its own, and nothing contributes more to unsatisfactory performance than thinking it is. Actually the desuperheater is only one the most important, to be sure – of 12 distinct system components (listed below). So system engineering is a must. Neglect any one component and you may doom the system to failure, no matter how excellent the design and engineering application of the other eleven.

In the less serious case the finished system works all right, but individual components are greatly over specified. Example: a saturated-steam system is equipped with a temperature recorder which, of course, records the same temperature over and over again. Here is a feature that isn’t needed at all. Its cost is wasted money.

When the finished station cannot perform its job, the situation is of course much more serious and immediate. Under specification of a single item can throw off the whole system. Example: a desuperheating station is carefully designed for 50:1 turndown-except that its control valve has a 20:1 range. This system will never work properly.

Follow these three rules and the odds are your system will cost less in the first place and operate better.

Use chart above to select proper l-p steam line. Enter at steam pressure and follow slanting superheat-correction lines to l-p superheat: 42F in our example. This is point A. Proceed horizontally to steam flow: 50,000+5400=55,400 LB per hr. This is point B. Use next larger pipe size (10-in.-ID pipe in our case).

Let’s say you have 50,000 lb. per her of 300 psig 600F steam that you want to reduce to 50 psig, 340F (42F superheat).

First check the steam tables and get enthalpy at both conditions. It will come out to 1313.6 Btu per lb. for initial conditions, 1202.0 Btu per lb. after the desuperheater. Heat to be removed in the desuperheater is the difference in enthalpies: 1313.6-1202.0=111.6 Btu per lb.

Next find cooling-water enthalpy. If you plan to use 200F water, enthalpy is 168.0 Btu per lb., again from the steam tables. Be sure available water pressure equals or slightly exceeds desuperheated-steam pressure, which is 50 psig in our case.

Figure unit heat to be picked up by the water: 1202.0 -168.0 = 1034.0 Btu per lb. Needed cooling-water flow is then merely a ratio of total heats; heat given up by the steam must be absorbed by the water. In out case: 111.6 x 50,000 = 1034.0 x lb. per hr. water flow. Needed flow come out to 5400 lb. per hr. This equals 11.2 gpm at 200F (sp. gr = 0.965).

1-Steam-pressure-reducing valve must have a turndown somewhat greater than that of the system; it must respond to plus and minus control signals even at maximum and minimum flow rates. Most valves are selected for a useful control range of 4 to 80% of maximum flow. If greater range is needed, use two in parallel operated in sequence by the same controller. Be sure the valve is equal-percentage type-needed for proportional control.

2-Piping to desuperheater should be as short as possible but long enough to reduce valve turbulence-five diameters long is a good rule of thumb. If valve and desuperheater are too close or if valve is too close to a pipe bend or other fitting, resonance may cause noise and vibration.

3-Desuperheater designs and their advantages and limitations were covered in POWER, Feb 1962, pp 73-75.

4-Steam piping to sensing element must be long enough to allow complete water evaporation ahead of the sensing element-30 ft is a good figure. Use best possible insulation over this pipe section to help prevent false temperature readings (condensation can still occur on the walls of a 100F superheated line). Measurement error can be quite large especially at low flow rates when heat lost through condensation is a high percentage of total heat in the line.

5-Temperature-sensing element codes usually call for a massive thermometer well, but the very mass of such a well slows down rate of heat transfer and causes a serious measurement time lag. At low flow rates the problem is worse yet; at 20 fps, for example, rate of heat transfer is only 25% as great as at 200 fps. Sometime it’s sufficient to simply improve contact between thermometer bulb and well. But in the other cases a special well may be needed-perhaps an extended surface type. In very severe situations a thermocouple or resistance thermometer must be used to speed up response of the overall measuring system.

6-Temperature transmission is another place where time lag can be serious. Mercury filled systems are usually good up to 25 ft; beyond that, air or electric transmitters may do better.

7-Temperature controller must have an adjustable proportional control large enough to match response characteristics of the entire desuperheater system. Automatic reset prevents drift in control point. Rate action is seldom needed, but if it is provided, complete cutoff should be possible.

8-Water-control valve must have an even greater range-ability than the pressure-reducing valve (recheck item 1). Two valves may be needed to get this range-one larger and one small. Be sure overlap between valves is not too great; don’t let pressure drop get to the point where it causes cavitation, damaging seat and plug. If high pressure drop can’t be avoided, use a self-acting pressure-reducing valve upstream of the main control valve.

9-Pressure-sensing element should always be downstream of the desuperheater, as near point of steam use as possible.

10-Pressure controller must prevent large pressure variations which might interfere with temperature control. So it needs an adjustable throttling range and automatic reset.

11-Piping to point of use should be as short as possible and adequately insulated. Entire desuperheater station should be located near point of use, rather than steam source.

12-Desuperheating water is completely evaporated. Water must be absolutely pure since any impurities deposit as scale. Water pressure must be high enough to satisfy desuperheater needs, but not so high that the control valve cavitates.